- Project News

- Your current location is:Home > News > Project News >

Audi FAW customized sandwich integrated panel is successfully launched

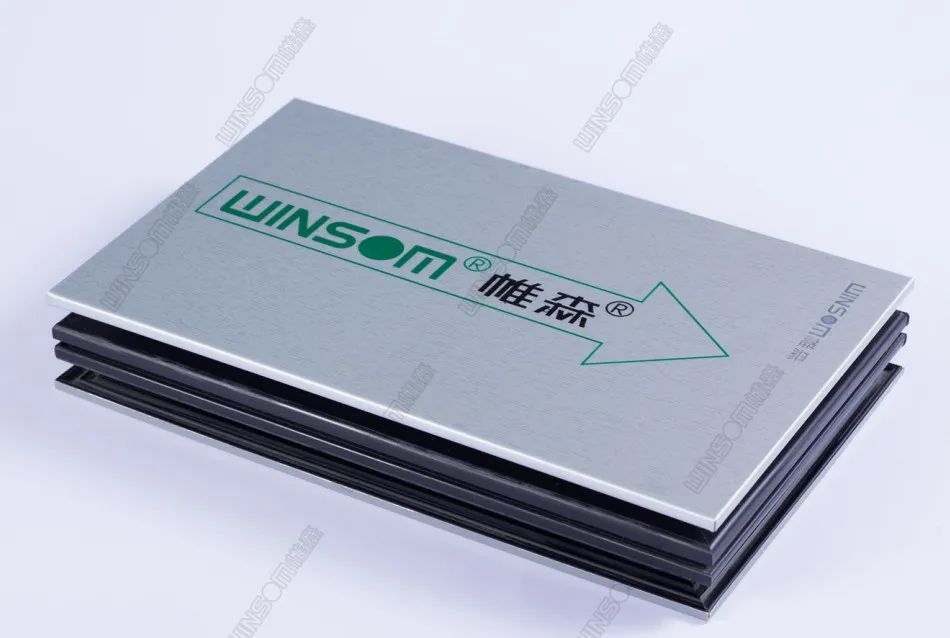

Have you heard of "MWCP180 Sandwich Integrated Panel"? It's a customized product developed by Winsom, an upgrade and high configuration version of sandwich panel.

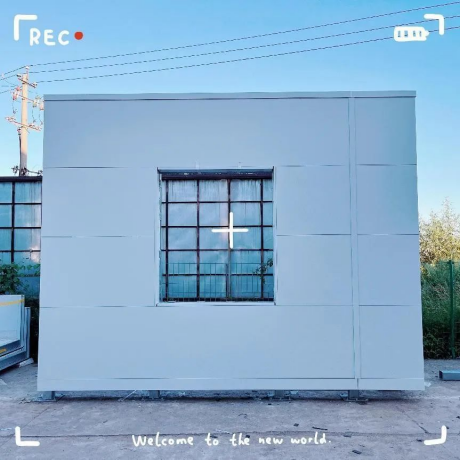

As the largest new energy vehicle factory in China, Audi FAW New Energy Vehicle Project is also the first time in the automotive industry to use 180mm thick sandwich integrated panel as the wall enclosure. The thermal insulation performance of sandwich integrated panel is closely related to its thickness. Audi FAW New Energy Automobile Production Base proposes to build a green factory, and sandwich integrated panel also plays a role as a green building material.

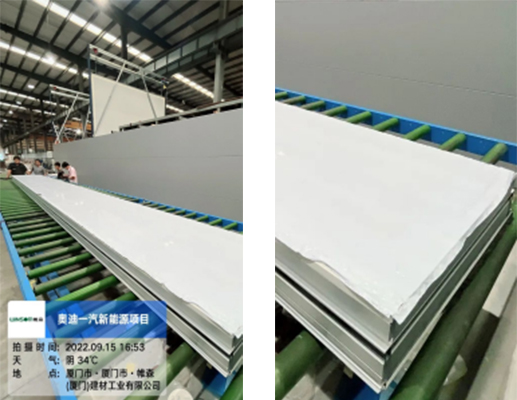

On September 16, 2022, the first panel of project was successfully launched, marking that the project has officially entered the stage of mass production and supply. All designers and loyal users of Winsom must be curious about how did these raw materials change from this

to this

High quality products

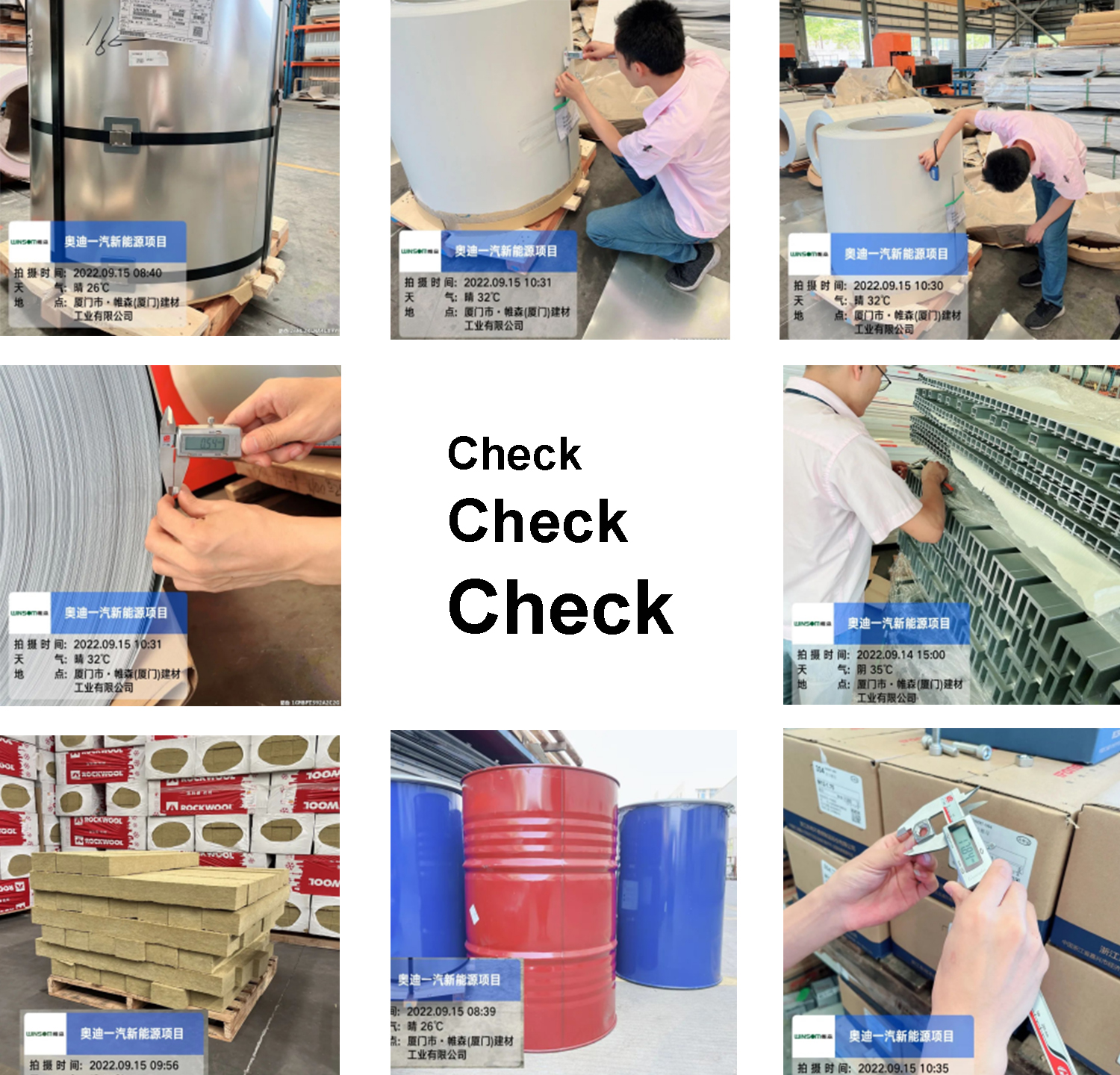

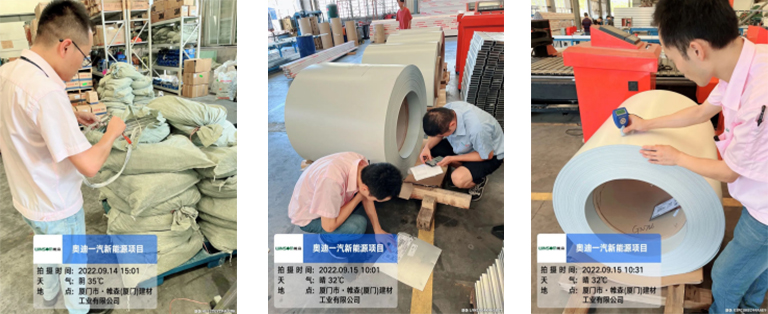

First comes from the selection and control of raw materials

Winsom has always selected high-quality raw materials at home and abroad: steel coils from Baosteel, extrusions from Feng Aluminum, rock wool from Rockwell and German Henkel adhesives, etc,

Only raw materials are guaranteed, can the product stability be guaranteed.

Do you think the materials can be warehoused once they arrive?

No~No~No!

They also need to pass multiple inspections.

Only when the inspection standard is met,

can be stuck with a green label,

Qualified Green Label

And eligible for production use

Sandwich integrated panel has the functions of heat insulation and sound insulation, and can be directly used for the wall enclosure structure.

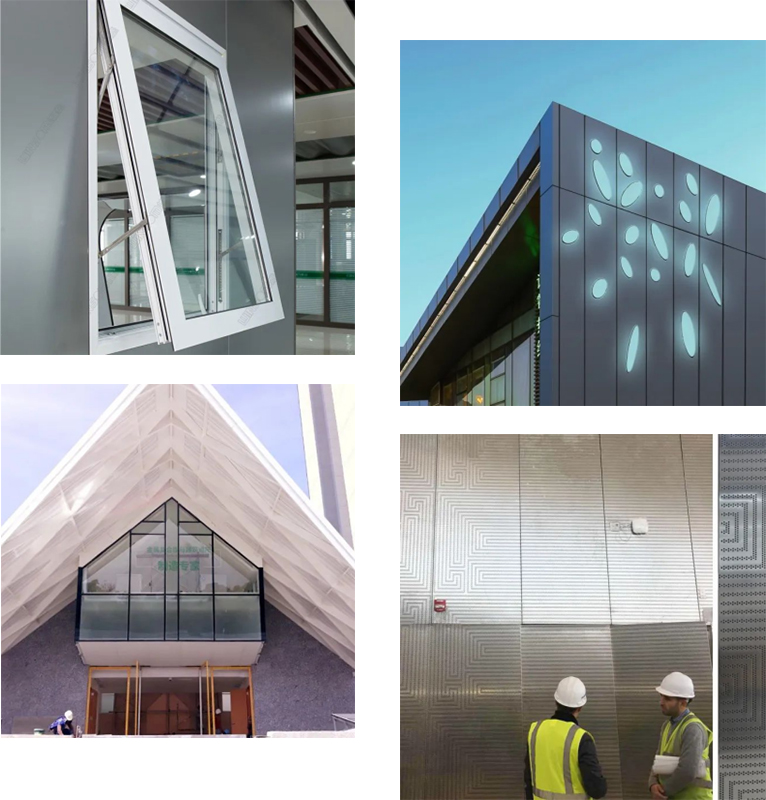

Winsom products are successfully used in many high-end industrial factory projects,

Including FAW-Volkswagen, FAW Audi, Hongta Cigarette Factory

Shanghai ABB Robotics Future Factory.

After the raw materials pass the factory inspection, they are formed through CNC automatic rolling → extrusion framing → rock wool cutting → CNC automatic gluing → assembly → CNC hot pressing composite → sealing → inspection and packaging,

This "Metamorphosis" was finished,

Like a little magic trick,

continues to be performed in Winsom factory,

However, this "show" has not been completed yet.

During the production process, each process needs to be inspected one by one. The quality inspection engineers are conducting various tests in our quality laboratory through random sampling. Only when they pass, the next process can be carried out.

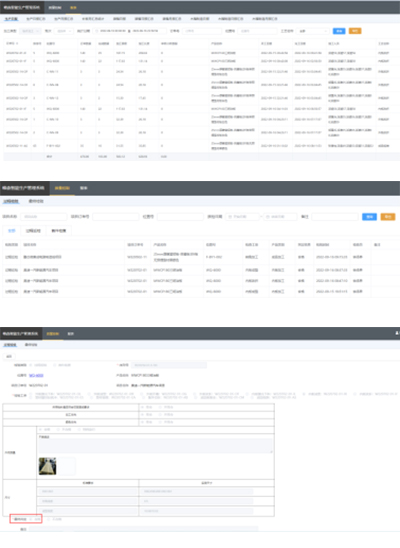

In order to keep the whole process of product production under control,

Ensure stable product quality,

We also have secret weapons——

PSMS intelligent production management system.

The system provides each panel with an independent ID number,

Through the "ID number", not only the whole production process of each panel can be monitored, the quality responsibility can be traced, and even the packing and delivery, project progress can be viewed in real time through the PSMS intelligent production management system.

True gold fears no fire,

Good quality can stand test!

Beside being used as a building wall, the high-quality sandwich integrated panel can also be used in indoor partition walls, suspended ceilings, and even waterproof roofs. It has a very rich range of color and finish to choose. What's more, Winsom can customize sound absorption, anti-collision, lighting and other functions according to needs.

There's nothing that Winsom can't do except that you haven't thought about it. If you have an idea, Winsom will have a package solution.

Let's wait for Audi FAW new energy vehicle project to show up!

END