- Product News

- Your current location is:Home > News > Product News >

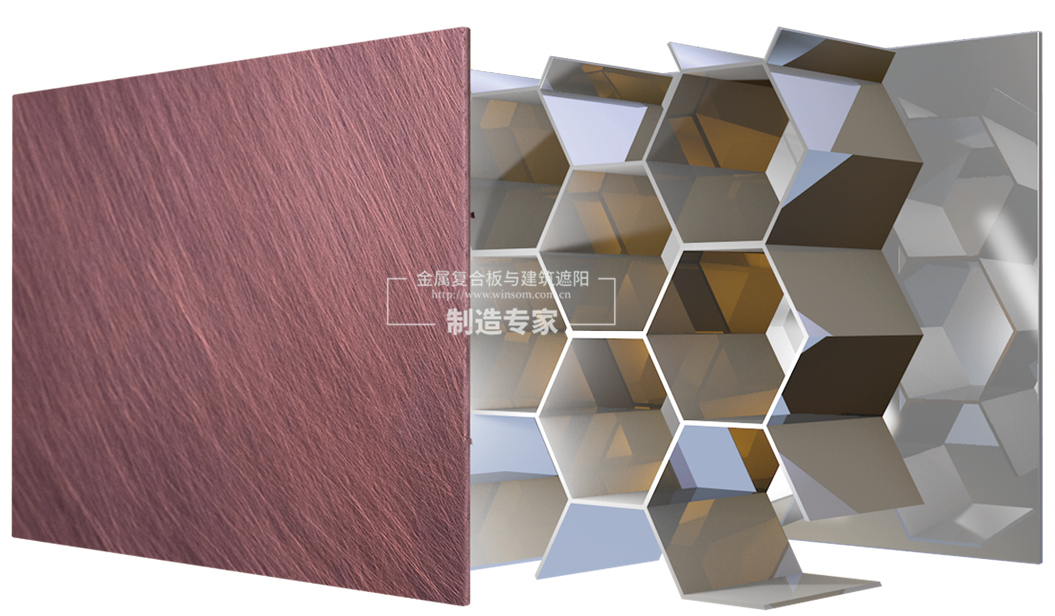

Copper Aluminum Composite Honeycomb Panel

Copper-aluminum hot-melt honeycomb panel is a kind of composite material based on honeycomb structure. On the premise of remaining the original copper texture and appearance effect, maximum use aluminum to take place of precious copper to save up social resource.

_看图王.web-8b3118d5-59f8-4ca6-b952-72cffa7881f6.png)

Copper-aluminum hot-melt honeycomb panel adopt honeycomb sandwich structure, front skin is copper-aluminum rolling sheet (consist of copper layer and aluminum layer, formed by rolling), the core is hexagonal honeycomb and back skin is aluminum. The internal cavity of the composite structure can be customized indoor and outdoor functions for buildings such as heat preservation, sound insulation and fire prevention. It is one of the few architectural decoration products integrating high-grade copper surface decoration and functional protection in today’s society. It will become the mainstream of architectural decoration in the future.

The Switzerland architect Herzog & Meuron once said: "No matter what materials we use to build a building,our main purpose is to find a special encounter between building and material. Material is interpreting the building, and we also make the building show the material used to build it, making the material 'visible'."

Copper-aluminum hot-melt honeycomb panel create the “visible”, which means the decoration material keep harmony with building style, the copper panel reflect the architectural style with time goes by. Behind the “visibility” express the core of modern industrial wisdom, environmental protection and energy saving industry wisdom, both of them completed a perfect integration.

Winsom Copper-aluminum hot-melt honeycomb panel has been widely applied to the interior and exterior of Erlitou Site Museum of the Xia Capital, which is the largest scale of site museum in the world as well. The perfect combination of building and material, either relying on each otheror complementing each other to complete the perfect integration of historical wisdom and modern technology.