- Product News

- Your current location is:Home > News > Product News >

Sandwich Panel Walling System

Walling is the top priority of architectural energy- saving design. It is proved that Winsom sandwich panel walling system is a set of high efficient energy- saving walling solution, which can achieve the integration of fire resistance, heat insulation, sound insulation, decoration and walling functions. Horizontal, vertical, slant, etc multi-directional installation is possible according to architectural design. Meanwhile, thickness and color can be customized base on functional requirement to achieve both economic and aesthetic.

The remarkable big span capacity of Winsom sandwich panel benefit from excellent overall strength. While, this unique strength come from panel itself structure strength and bonding strength between steel skins and core guaranteed by patent technique. With the largest professional hot pressing equipment in industry, the maximum size Winsom can produce is 12000mm length x 1500mm width (depend on wind load application environment and panel thickness).

Winsom sandwich panel is customized according to specific project; and packing arrangement also follow the principles of safety and convenience. No second fabrication at site, panels can be directly installed which ensure fast & high-efficient installation and greatly shorten construction time.

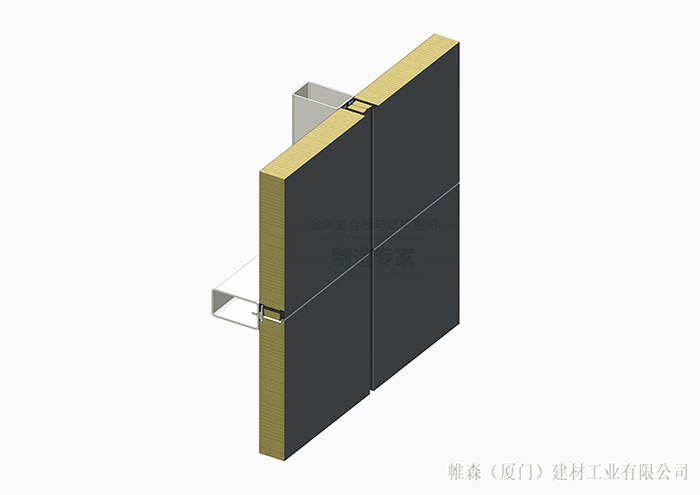

Winsom sandwich panel walling system with plug-in installation, use specific clamp to fix panel on the support rather than riveting or penetration installation, which keep panel in good condition and manage thermal movement caused by temperature change.

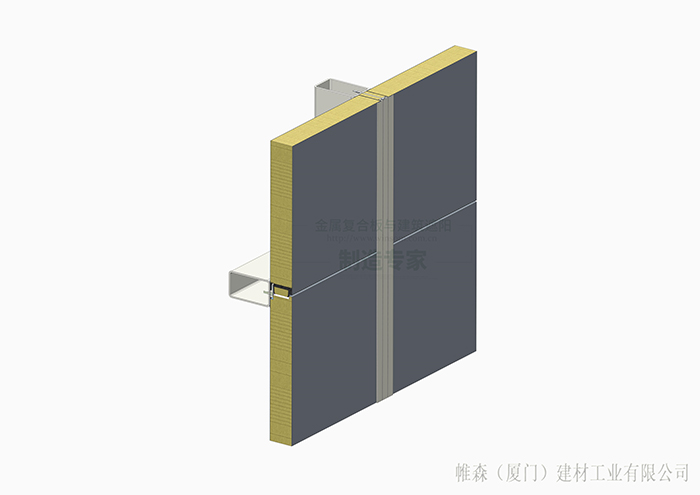

The joints connection among panels are easy to cause cold bridge. Both front and back skins of Winsom sandwich panel are connected respectively by modified PVC profiles that completely avoid cold bridge and enhance installation strength. Meanwhile, double EPDM sealed gaskets in fixing joint ensure water tightness and air tightness for walling.