- Enterprise News

- Your current location is:Home > News > Enterprise News >

Winsom Intelligent Production Safety Management System (PSMS) was successfully put into use!

Intelligentize & Informationize Production Management Mode

After nearly one year of establishment and debug, Winsom Intelligent Production Safety Management System (PSMS) was successfully put into use, opening the company’s intelligentize and informationize Production Management Mode.

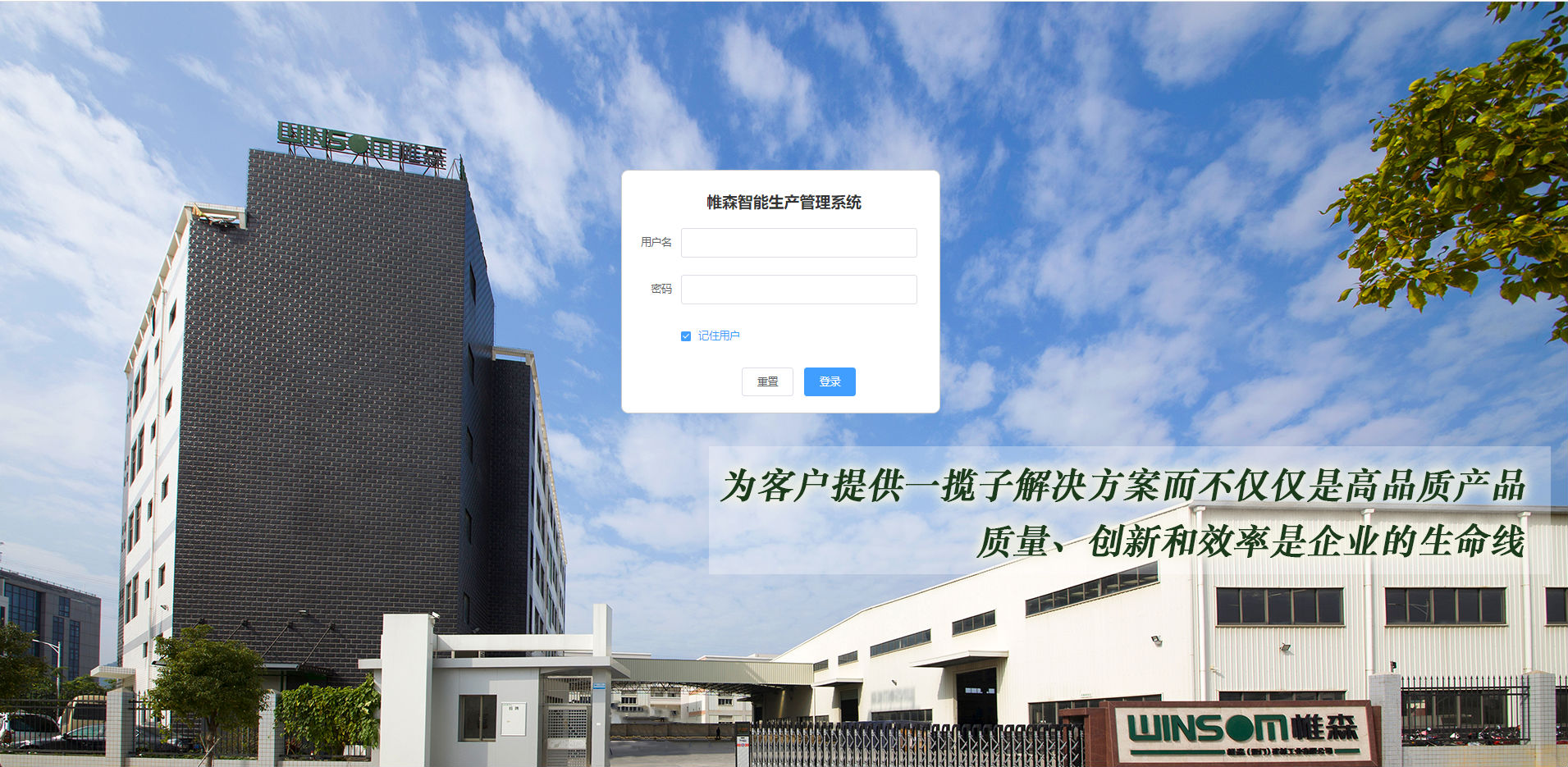

Login

PSMS login web interface

Winsom PSMS is a set of intelligent management system for dealing with the existing management problems in the factory’s production process. It aims to establish standardized, accurate and timely production management database, establish an integrated production management system to achieve orderly, high-efficient, low-cost production management system to effectively control the production process, and improve the production efficiency.

Assist company inproduction management

1. Realize intelligent schedule of production plan, reasonable planning of production schedule;

-af1c3528-013a-4c88-8662-74201aded671.jpg)

2. Realize production schedule transparency, can be able to track and adjust production capacity in real-time, in order to make best use of the production capacity.

3. Ensure timely and accurate feedback of production data to avoid lag and error caused by artificial input.

4. Regular production process, make procedure accurate and recordtraceability.

Quality control throughout the whole process, improve quality management level.

1. Support track production and quality management, ensure processinspection (inspection at each process) be traceable and monitored, timelyprevent the inferior products flowing into the next procedure.

2. Finished products inspect, assure products quality, superior goods areput in storage, avoid unqualified products out of factory.

3. Achieve the responsibility of a designated person, strictly abide by qualitycontrol standards.

_看图王-06c41874-7a68-477c-8548-7d22f0cfbe44.jpg)

Fully control data, which is beneficial to improve quality and efficiency and reduction cost.

1. Supervisory control whole production data, which timely and effectively find the problems encounter in production process.

2. Refined management of each process caneffectively improve the utilization of personnel and equipment

3. Combined with computers, tablets, printers, codescanners and etc. smart devices, it enables whole production process realize paperless management.

4. The system is helpful to improve employee’s skill, strengthen enterprise internal control, enhance collaboration management, promote enterprise overall efficiency.

5. It can be accessed through Internet to understand the production progress remotely in real-time, help customers arrange construction schedule timely, avoid work stoppages and work delay, create value for customers, improve customer satisfaction.

Intelligentize and informatization

Winsom PSMS integrated material, equipment, staffand process instructions and quality control, integrated factory resource. On the one hand, collects and transmits production data in real time, realizes transparency, management informationize and digitization of production site,which is helpful to administrator effectively put into effect. On the other hand, via analysis and tracing production data, put forward a kind of method of improvement production resources, production organization and management, and optimize production and quality management systems, the enterprise not only improve efficiency and reduce costs, but also improve manufacturing competitiveness.

Winsom PSMS is an important part of the enterprise’s realization of informatization and industrialized, fully make use of its advantage,Winsom will use informatization to drive industrialization, then to promote informatization, it will step to new stage onintelligentize, achieve a sustainable development mode.